Services

Apart from developing and manufacturing parts according to individual customer requirements, Gebr. Denker GmbH & Co. KG also produces a large standard range of plastic carrying handles for the cardboard and packaging industries.

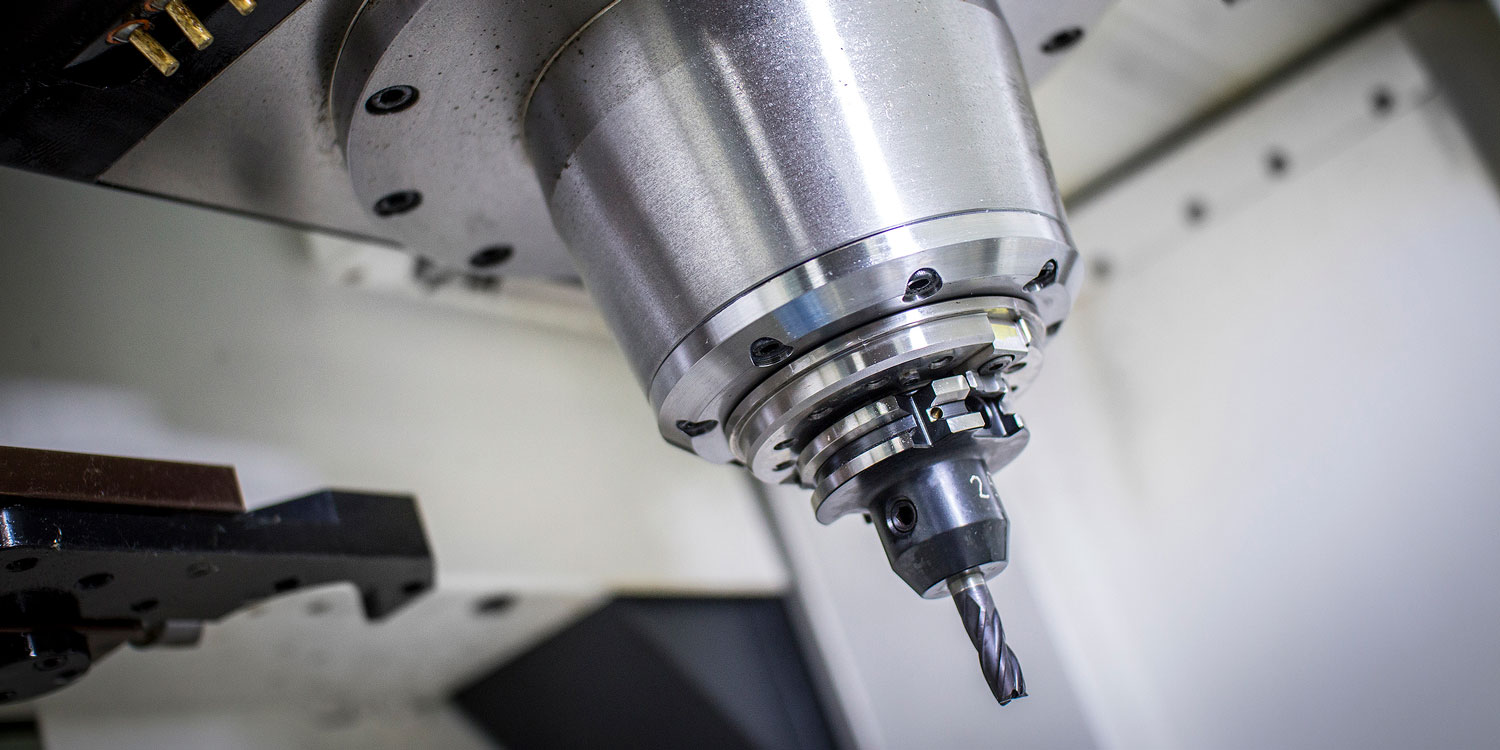

Tool Making

In collaboration with customers from a wide variety of industries, Gebr. Denker GmbH & Co. KG develops products, manufactures prototypes and implements pilot series. Our in-house toolmaking department ensures that orders are processed quickly and smoothly.

Our engineers and technicians will accompany you from the idea to series-production readiness. Whilst impressive tool stocks provide for flexibility and reliability, competent and experienced employees ensure results of high quality and precision.

Plastics Processing

Gebr. Denker GmbH & Co. KG has processed plastics since 1937. Whilst the initial focus was on the manufacture of products made from thermosetting plastics, thermoplastic polymers of all common types and qualities have been the only materials used since 1950. The entire production is aimed at the implementation of individual customer requirements and makes a wide variety of subsequent treatments and finishes possible. We manufacture products for the sanitary, engineering, packaging and electronics industries. Our in-house shipping department ensures that the products are stored, assembled and picked, and finally shipped to any location worldwide.

Surface finishing

Gebr. Denker GmbH & Co. KG focuses on the customer and their wishes. Hence, it goes without saying that, depending on the customer‘s wishes, surfaces are refined, varnished or finished with screen or pad printing.

- Coppering

- Matt chrome finish

- Gloss chrome finish

- High-gloss gilding

- Vacuum metallising

- Printing

We will be happy to provide you with information about the many surface finishing options available.

Assembly

We will also be happy to take care of complex component assemblies and the picking of worldwide shipments. As is the case with the manufacture of your products, we guarantee high quality and reliability.

- Custom packaging

- Assembly of complete units

- Picking of single components for assemblies

Quality Management

The high requirements of our international customers imply a consistent and process-oriented quality management, which is why our company is certified to the DIN ISO 9001/2015 standard.

Whilst during production inspections form part of our own quality standard, 100% checks are carried out upon request. Continuous investments in quality and reliability, state-of-the-art technologies and employee skills in all areas of the company guarantee consistent quality in the areas of development, production and service.